Moving to a circular economy is a high priority on the EU green agenda and, even if there is a clear consensus around this, there are still huge challenges and work to be done to achieve more circularity in the different sectors. As a first step, it is important to better understand how this transition will affect the industries and workers in Europe. The European Social Partners have already worked on these aspects, and in October 2020, launched a report detailing important recommendations.

IndustriAll Europe is also taking part in this essential transition and has joined an ESF project led by Reset.Vlaanderen, a Belgian organisation, to better understand how workers and trade unions can, in practice, work towards more circularity. As the challenges are very different depending on the sectors, the project is focusing on the metal sector, on one hand, and on the chemical and plastic sector, on the other hand.

As part of this project, industriAll Europe, together with two Belgian organisations - Reset.Vlaanderen and Bond Beter Leefmilieu - organised a workshop on 24 February. The workshop gathered experts and trade union representatives from different countries to evaluate the challenges of the transition towards more circularity in the metal sector.

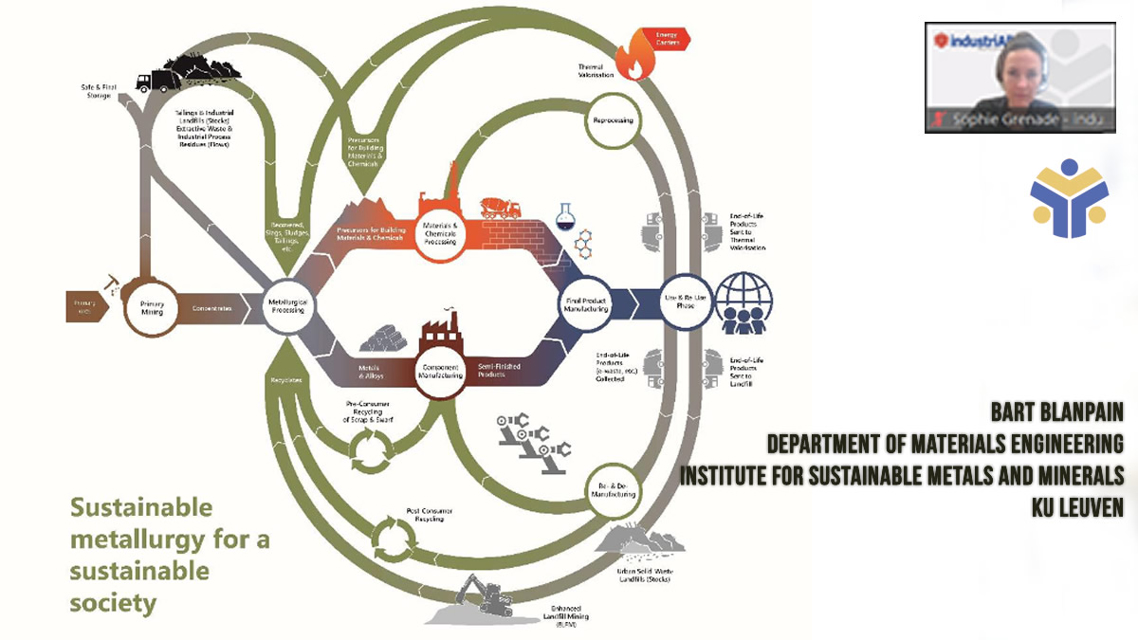

Two experts (Bart Blanpain, Professor at the Institute for Sustainable Metals and Minerals at KULeuven, and Kamila Slupek, Sustainability Director at Eurometaux) shared explicit data showing the necessity of a more circular use of metals and minerals to meet the growing demand, notably for the infrastructure needed for the climate-neutral economy (batteries, solar panels and wind turbines). But they also showed the reduced need of energy for recycling, as well as the reduced GHG emissions, compared to extraction and primary production.

Pure metals scrap recycling has a high energy saving compared to production on the basis of primary raw materials (e.g. 95% for aluminium and zinc, 85% for copper vs. primary) and it is also important to remember that recycling and circularity is already in the business model of Europe’s metals industry (over 50% of all base metals produced in Europe are made from recycled sources).

Despite this, there are many challenges ahead and the trade union representatives from Germany, France and Belgium shared concrete examples during the workshop. IG Metall in Germany explained how one company has transitioned towards more circularity in the aluminium sector. There, workers have expressed their concrete demands to the management: a clear strategy on CO2 neutrality of the company, a support of the company’s transformation processes, necessary investments, creation of new jobs in new domains in substitution for lost jobs, and research and development onsite. This example can inspire other trade unions facing similar transitions in their companies.

In France, the challenge of the subcontractor (recycled metals providers) was highlighted. Indeed, large companies are supplied by recycling companies, which are more often SMEs with no social dialogue. Subcontracting recycling companies is also a challenging question for trade unions in Austria, as these companies are not always covered by the same collective agreements and do not have works councils. The idea of having a ‘social charter’ (with high occupational health and safety provisions, for example) for the companies using recycled metals was largely shared by the participants as a concrete tool at the disposal of trade unions.

In Belgium, emphasis is placed on the importance of industrial symbiosis, gathering metal-producing companies, metal processing and product manufacturing, and waste valorisation with other key actors, such as universities and non-profit actors.

These examples are key inputs for the project, which aims to reinforce the knowledge of trade unions about the circular transition, and exchange best practices from different countries.

Contributions from this workshop show that the transition in the metal sector is not something for the distant future, but that it is already happening right now, in many concrete projects in companies across Europe. The current context of rising energy and raw materials prices - which has strong impacts on energy-intensive industries - also shows that circular economy is the solution for the future of these industries, with less energy and raw materials input when possible.

IndustriAll Europe will hold another round-table discussion on 24 March, focusing on the circular transition in the chemical and plastic sector.